Condensation in your air system

Condensation in your air system let’s see how we can deal with this annoying residue that accumulates in the compressor tank. compressor tank. First of all, there is a difference between condensate generated by an oil compressor and a dry compressor, and in any case it must be removed from the bottom of the tank.…

Essential strategies for more efficient production

With the door (finally!) closed on 2022 and the worst of the COVID-19 pandemic seemingly only a memory, manufacturers are looking to the future with a new outlook and criticism. Supply chain problems, raw material delays, labour shortages, rising costs and increasing demand are forcing manufacturers to increase productivity and efficiency. 3D printers and photopolymerisers…

Why is it important to dry compressed air?

Compressed air used in dental surgeries, if not properly treated, contains a high amount of pollutants, most of which is water vapour. The latter is the main cause of premature corrosion and wear of equipment connected to the dental unit, mainly air turbines. All this translates into higher operating and maintenance costs for the equipment…

Vacuum mixer for dental technicians.

Nowadays, it has become an indispensable piece of equipment for the dental laboratory. It is mainly used to mix plaster and veneer, some also have the ability to work on silicones. What are the requirements that this instrument must have? First, it must be equipped with a vacuum pump, preferably a dry one, as it…

MICROMOTORS – MAINTENANCE

Remember to carry out all control or maintenance operations with the appliance’s socket unplugged. Here are a few simple and practical tips for doing some maintenance on your laboratory micromotor. Obviously these tips will not make your equipment ‘eternal’ but they will help you keep it in a correct mechanical state which will also benefit…

Micromotors, how to choose them?

Laboratory: The dental technician must pay close attention when choosing a micromotor, an essential tool in the dental laboratory, based on several criteria. The first important consideration is ergonomics, i.e., the shape, weight, balance and working position of the tool to ensure comfortable, relaxed and precise use. In addition, the internal technology of the tool,…

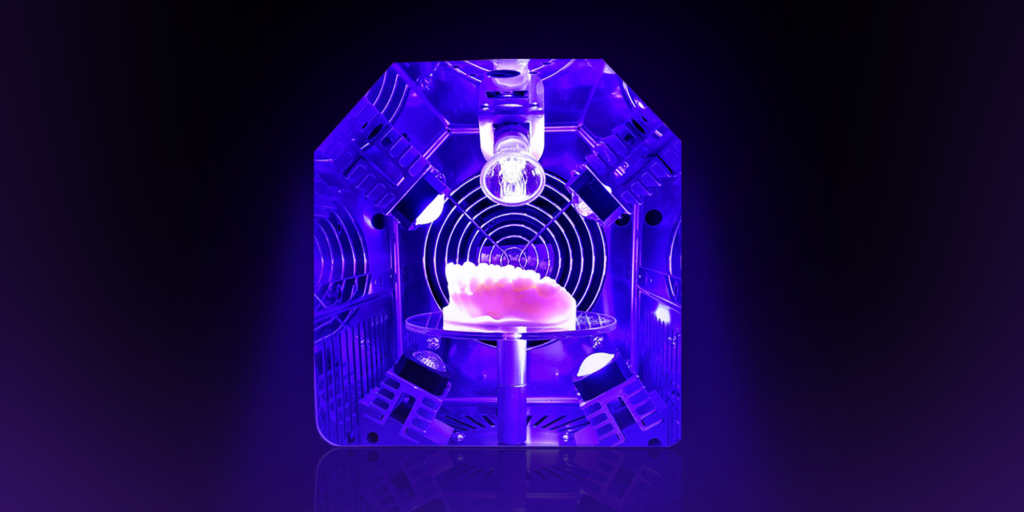

3D PRINTING RESINS – POST CURING

3D PRINTING RESINS – POST CURING Having performed 3 D printing, another key step is post curing, which is the complete polymerization of the print to be performed with special equipment that provides UV light at a certain frequency to completely fix the polymer molecules. Models produced with resin printers are not fully cured through…

3D PRINTING RESINS – PRINTING CHARACTERISTICS

There are a huge number of 3D printing resins available on the market, all with different properties and prices. Because of the difference in resin chemistry, an evaluation of the mechanical properties can help you choose the right resin for your application. In many cases a 3D printing resin supplier provides a set of mechanical…

Our New Mixer “MX5 EVO SYSTEM”

System created to improve the mixing of our mixers, the rotation axis has been inclined by 10 ° allowing a better handling of the cup and a more complete mixing of the product. The mixture is made more homogeneous by exploiting the gravity that makes it slide from the center of the cup towards the…

SMART support

Support for light curing of composites Transparent plexiglass support specifically designed for the polymerization of dental crowns and bridges, due to its size it is suitable for all types of UV ovens. It does not generate shadows on the workpieces, it is versatile as it has 57 holes for positioning pins and an alligator clip.…