WHAT ARE:

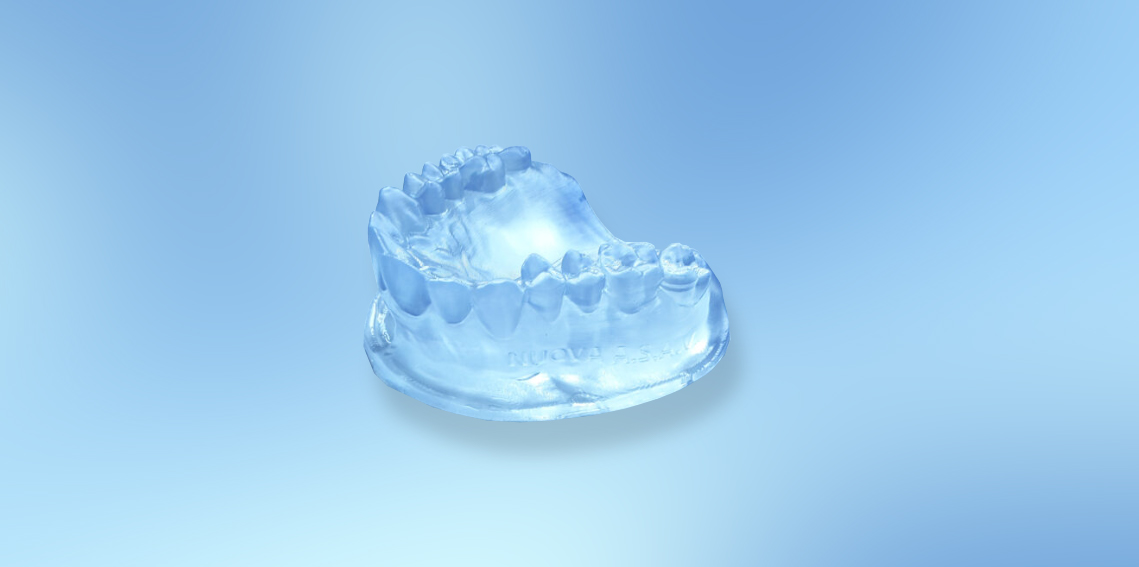

A composite material is a material consisting of two or more constituent materials, with significantly different physical or chemical properties which, when combined, produce a material with different characteristics from the individual components.

The individual components remain separate and distinct within the finished structure.

For this reason they must be perfectly distributed in the mass to be treated.

For dental use, at least some basic principles must be taken into account:

– The reactive stabilizer that catalyzes the hardening of the masses is UV light.

– The chemical-physical reaction that takes place is “exothermic” and must NOT exceed 72 ° C., Otherwise the

polymer chain does not close and will cause breaks and micro-cracks.

– the rise in temperature during the exothermic reaction is proportional to the difference between the

starting temperature (1) and its specific and optimal polymerization temperature (2).

Conventionally indicated at 47- 48 ° C.

(1) temperature of syringes that should be stored in the refrigerator …

(2) not exactly known, nor easily determined, and in any case variable from brand to brand.

PRECAUTIONS FOR USE:

Those who use composites know very well the conditions for having the best performance, therefore, cannot

forget the requirements required for the use of these materials.

Anyone who knows that composites must be pressed, spatulated and positioned, knows that they must have the right fluidity.

Fluidity that can only be achieved with the correct temperature, in the best conditions and without errors.

Therefore pay close attention to the various and improper working conditions to be avoided:

– heat syringes lying NOT upright or tilted,

– heat the same syringe several times,

– heat several syringes at the same time for a long time, then allow them to cool overnight

and then return to heat them again.

– In this way, in a conceptually incorrect position, the heavier components deposit at the bottom and those

lighter remain at the top of the syringes.

So every better fluidization of the composites, mistakenly and repeatedly performed, results in one

deterioration of quality and an uneven distribution of the components of the composites within the

subsequent works.

In other words, it is not just a fluidization problem that can be overcome with heating, as long as it is

properly executed.

Otherwise, the damage caused to the structural and aesthetic performance of the composite will be greater.

POLYMERIZATION:

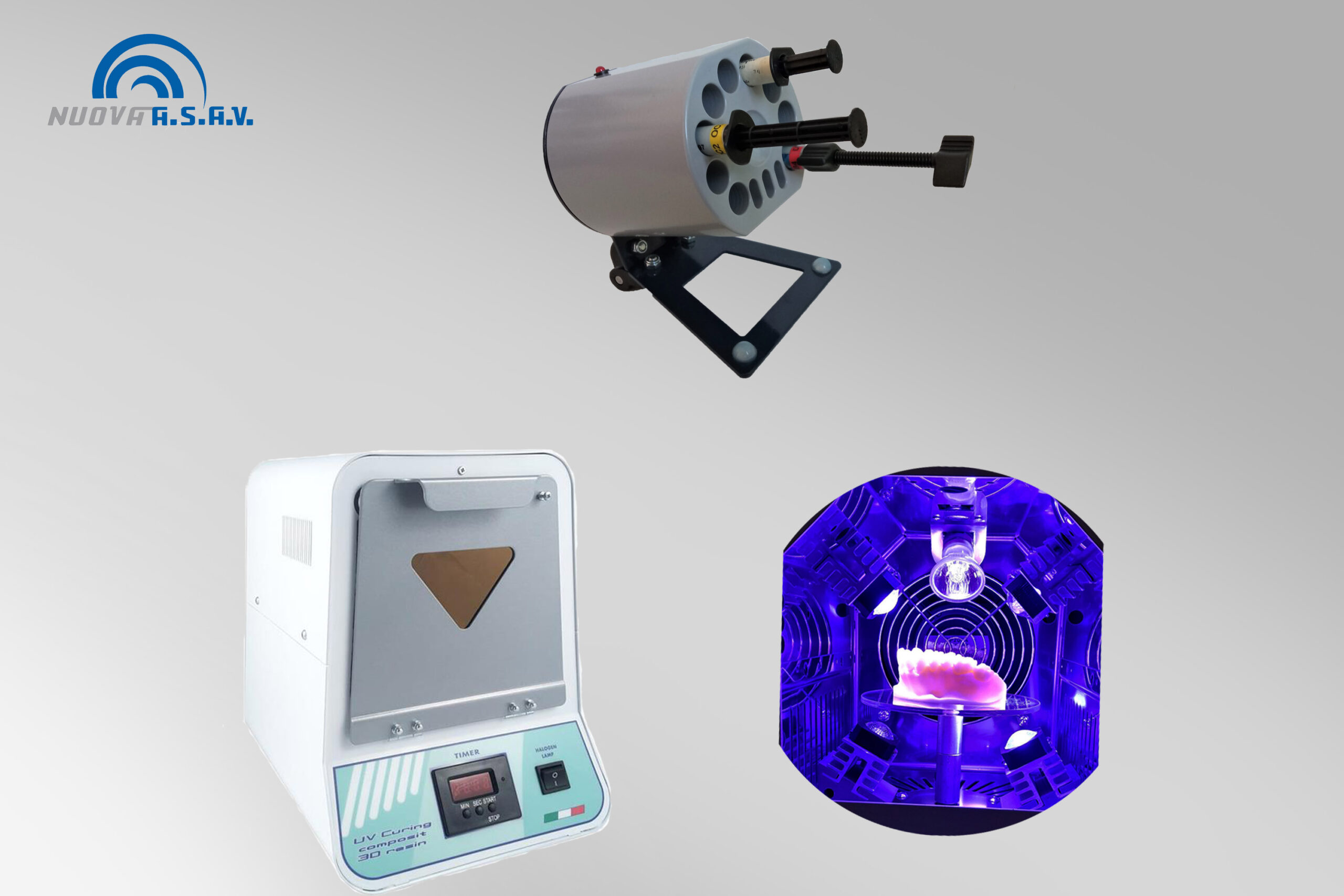

The polymerization of these composites is carried out with a UV light of well defined wavelengths, and each type of composite reacts effectively with a correct frequency which is not always the same as the competing product.

Usually the opaque can be more difficult to polymerize, it is recommended as well as in other cases to apply thin layers, then perform a prepolymerization on each layer and a final firing of 5-6 minutes.

During the final firing cycle it is important that temperatures do not exceed 45/50 ° C in order not to create surface tensions that would almost certainly end up cracking the applied layers.

Our FMP PLUS UV oven in this regard uses an intermittent LED light that allows a good degree of penetration of UV rays without overheating the material.